Sustainable building

Materials and resource

Assessing the life cycle of the whole building compares the calculated performance of the building design as compared to a typical baseline building. The intent was to optimize the environmental performance of products and materials. The building design calculations show a 21% or greater reduction in all six impact categories. The LEED requirement is a minimum of 10% in at least three categories:

- Global warming potential: 26% reduction

- Ozone depletion: 21% reduction

- Acidification: 26% reduction

- Eutrophication: 26% reduction

- Formation of tropospheric ozone: 28% reduction

- Depletion of nonrenewable energy: 35% reduction

Material transparency

The design team gave priority to materials from manufacturers that publish data on product ingredients and the life-cycle impacts of their products. These materials disclosures allowed the project team to make informed decisions that reduce negative environmental and human health impacts associated with building materials. Selecting products that offer disclosures supports positive market transformation by encouraging more businesses to adopt these practices. In addition, the project carefully vetted interior finishes such as paints, ceilings, flooring and wall panels for low emissions or low volatile organic compounds, which creates a healthier indoor environment by minimizing airborne pollutants.

Material and environmental impact: these graphs show the pollution and depletion effects of main building materials such as concrete, steel, wood, insulation, waterproofing, windows, doors, ductwork and plumbing. This type of analysis helped the team pick materials with minimal environmental impacts.

Construction waste diversion

As part of the demolition and construction process, waste is produced that typically is sent to a landfill. The design and construction team for this building created a sustainable and environmentally conscious waste management and demolition plan resulting in 80% diversion of waste from landfill in the construction process, 5% higher than the required minimum. This calculation includes the demolition of the existing building and site improvements where resulting waste products, such as wood, metal, cardboard, concrete and plastics, were diverted into a recycling facility rather than a landfill.

Health and wellness

The design team developed a Material Selection Protocol that prioritized human health, climate and ecology. This approach explored health and happiness, collaboration, inclusion, equity and fair trade to develop integrated design solutions aimed at reducing the embodied greenhouse gas emissions of the project. The protocol also aimed to intersect with local, regional and global ecological health, while recognizing regeneration and diversity as a critical component of this health. Through the process, the team identified redundancies in the design and simplified the materials palette to increase the “power of the purse”.

Active design

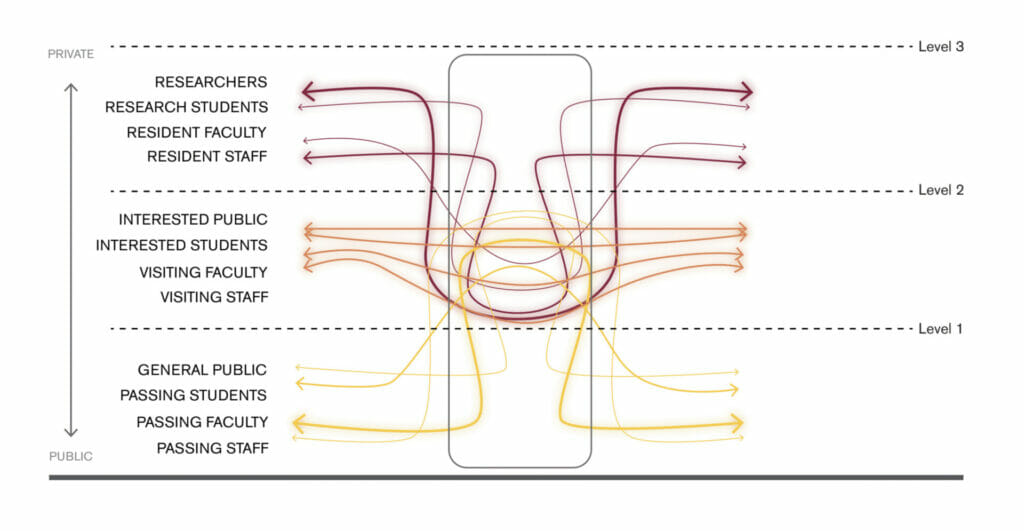

The ELAB was designed to encourage casual meetings, provide a place for informative displays about the research on all of the ASU campuses and create connections to other parts of the community. It includes Design for Active Occupants by pulling the stairs into the ELAB to encourage occupants to use the stairs instead of the elevators.

Urban flow

Located on a highly visible and congested corner of the campus, the project design encourages walkability with deliberate connections for people that want to move diagonally across the site in two different directions on grade or by using the pedestrian bridge that links a busy light rail stop with the north side of the campus on the second level. All the pedestrian paths offer the option of shade and include interesting landscape, science-on-display and historical features along the way.

Embodied carbon reduction

The project employs several strategies for reducing the carbon footprint of the building’s material. Void form (bubble deck) not only reduced the quantity of concrete, but it was also less expensive. The spheres made of recycled plastic are cast into the concrete deck replacing concrete that was not needed to provide the required structural support. The team also developed procedures to use concrete made with 40% fly ash in all areas of the project. The fly ash replaces the cement, the component in concrete with the largest carbon footprint. Fly ash typically makes finishing concrete difficult, but by working with the builder, the team was able to develop strategies to reduce the impact and lower the overall carbon footprint of the project.

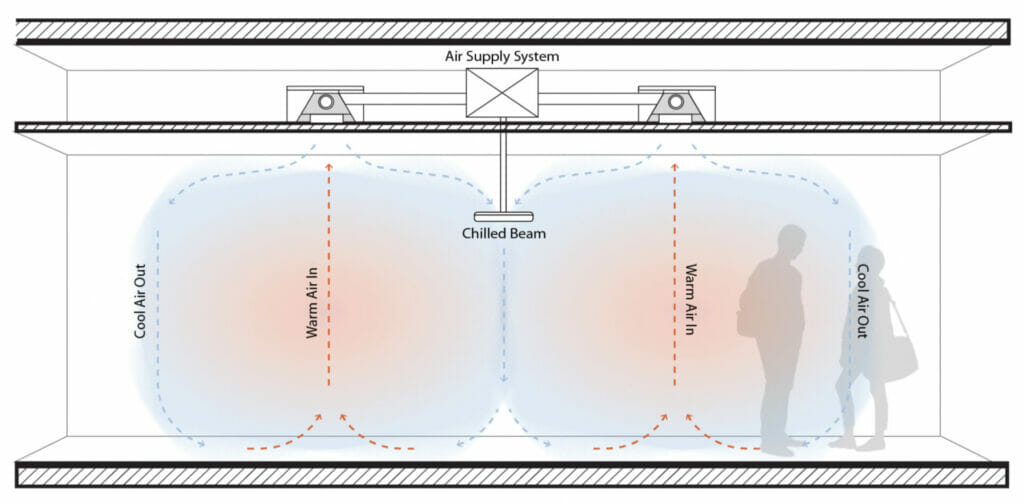

Energy reduction

The building relies on radiant cooling with chilled ceilings, active chilled beams and chilled sails. The building is significantly more efficient by almost completely eliminating the fan load associated with forced air systems. These systems optimize airflow and temperature delivery to efficiently meet thermal comfort. Smart controls and CO2 sensors allow the building to efficiently meet ventilation requirements to promote the health and well-being of the occupants.

The use of an air displacement cooling system in the auditorium tells the story of both energy efficiency and health and wellness. The displacement system optimizes delivery of air to cool people from vents under their seats and effectively deliver cool air where it is needed. From a health and wellness perspective, the displacement system allows for contaminated air to move upwards into stratified areas and away from the occupants

Energy modeling

Enhanced energy modeling from the beginning of the project helped the design team make informed decisions during design instead of testing locked-in decisions at the end of the process. Results included locating high energy uses on the north side of building and placing the lower energy use office spaces as a buffer to southern elevations. In addition, several energy conservation measures were analyzed to understand where the project could target reductions in energy consumption for both passive and active systems.