The Center for Negative Carbon Emissions DAC Testbed offer a variety of services led by a team with extensive research and field experience.

The Center for Negative Carbon Emissions Direct Air Capture Testbed is a world-class facility providing a comprehensive understanding of carbon capture and storage, climate policy, certification, sorbent development, supply chain and long-range planning experience for climate change mitigation.

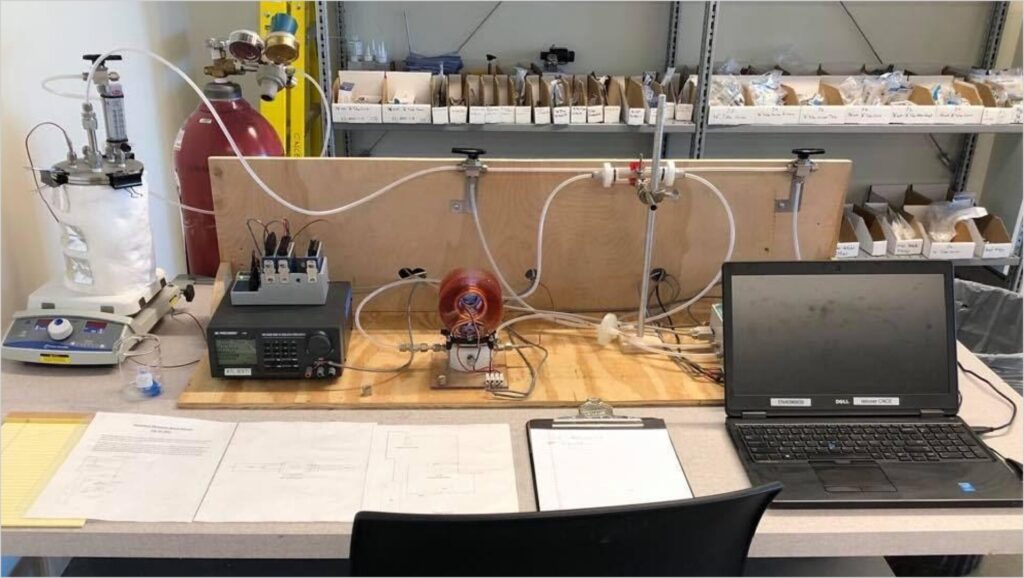

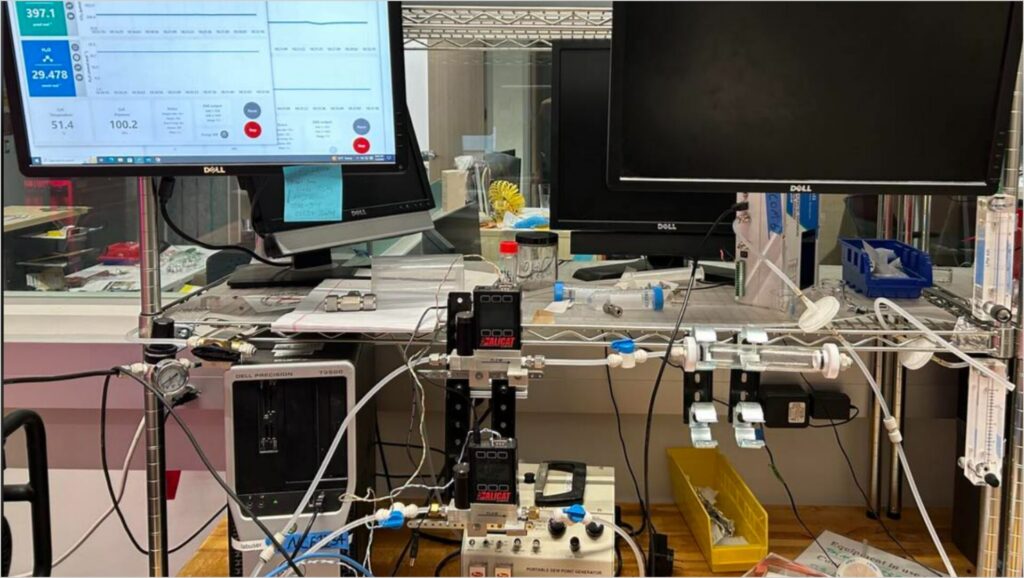

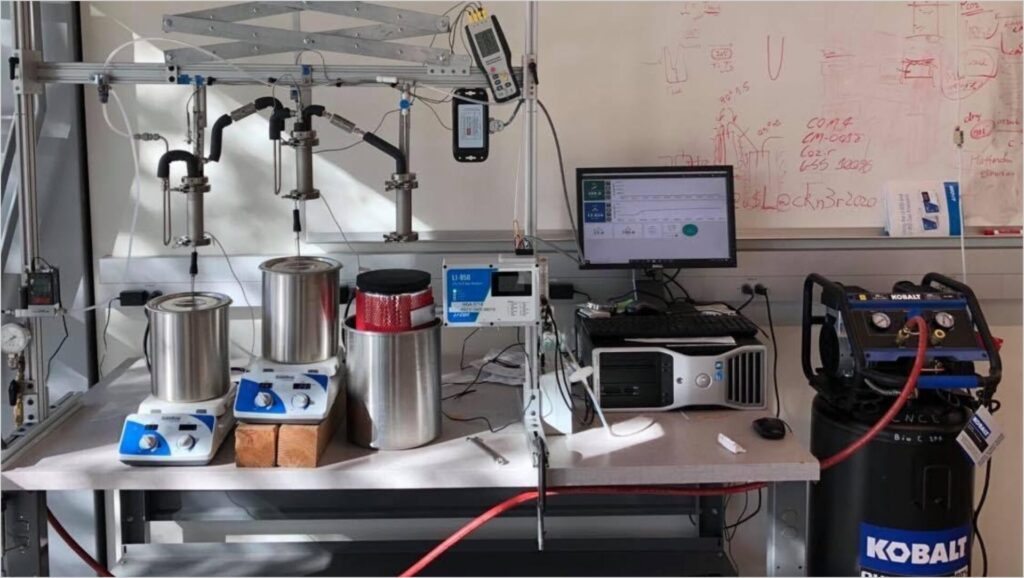

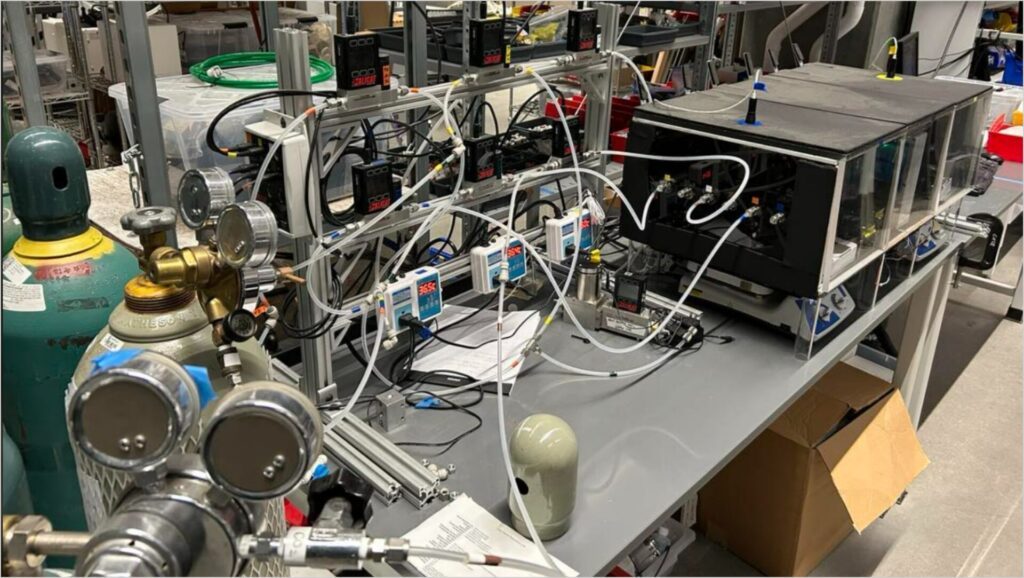

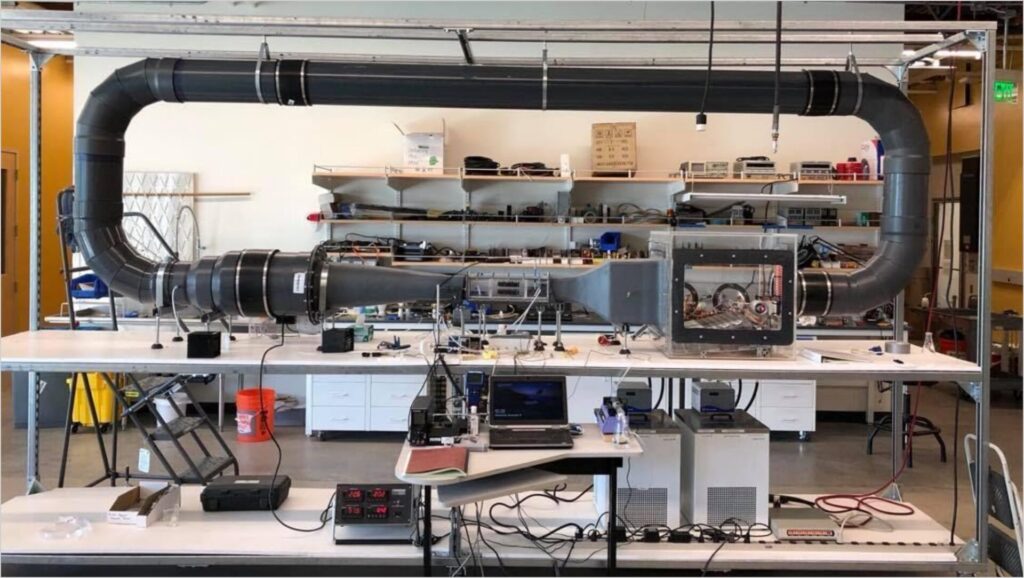

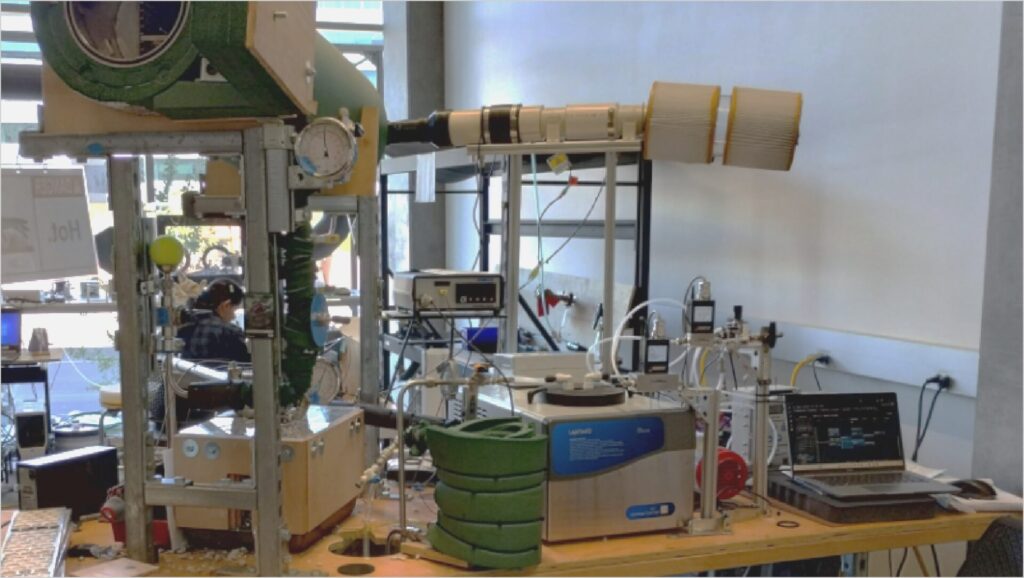

The CNCE DAC Testbed is home to several custom-made, state-of-the-art sorbent characterization systems that accommodate experimentation ranging from milligram to kilogram scales. This includes a methodology to quickly screen performance characterization of multiple sorbents for carbon capture in a short time, which accounts for sorbents to be scaled up from mg to kg scales. These methodologies evaluate essential environmental conditions (temperature, humidity, wind velocities) that affect sorbent performance.

The CNCE DAC Testbed collaborates with industry, national labs and academic researchers to synthesize a range of sorbent materials, process them into factors that optimize collecting CO2 from the air and extracting and concentrating CO2 from the sorbent, precisely and accurately measure its DAC performance, designing and fabricated customize DAC test equipment, and developing bench scale and pilot scale DAC systems since its inception in 2014. One of these successes was conducted in partnership with Carbon Collect LLC and involved the scale-up of a sorbent from mg to hundreds of kg, as well as a program that placed the MechanicalTreeTM prototype on ASU’s Tempe campus for technology testing and evaluation.

Center for Negative Carbon Emissions facilities can be divided into distinct categories related to carbon removal:

- Sorbent capacity, kinetics characterization and scale up, from mg to kg

- Outdoor pilot scale test pad experiments for carbon capture and/or storage (technology validation studies)

- Data interpretation and presentation based on client or ASU research

- Technical results interpretation, analysis and application recommendations

- Sorbent synthesis and form factors for better performance

- Feasibility studies for climate mitigation applications

- Certification of CO2 removal services, advice, structural application and proof concept

- 3rd party CO2 removal certification and carbon durability analysis

- Mathematical modeling

- Industrial carbon management analysis, including recommendations for alternative applications and approaches

- Analysis of carbon storage including feasibility, site preferences and alternative considerations

- Conceptual analysis service that may include recommendations for new technologies or applications

Service Center bench-scale systems

Contact the Center

If you are interested in collaborating with CNCE on developing new sorbents, evaluating DAC sorbent materials, form factors, bench and pilot scale DAC systems, or other opportunities, please fill out our contact form and a member of our team will get back to you shortly.